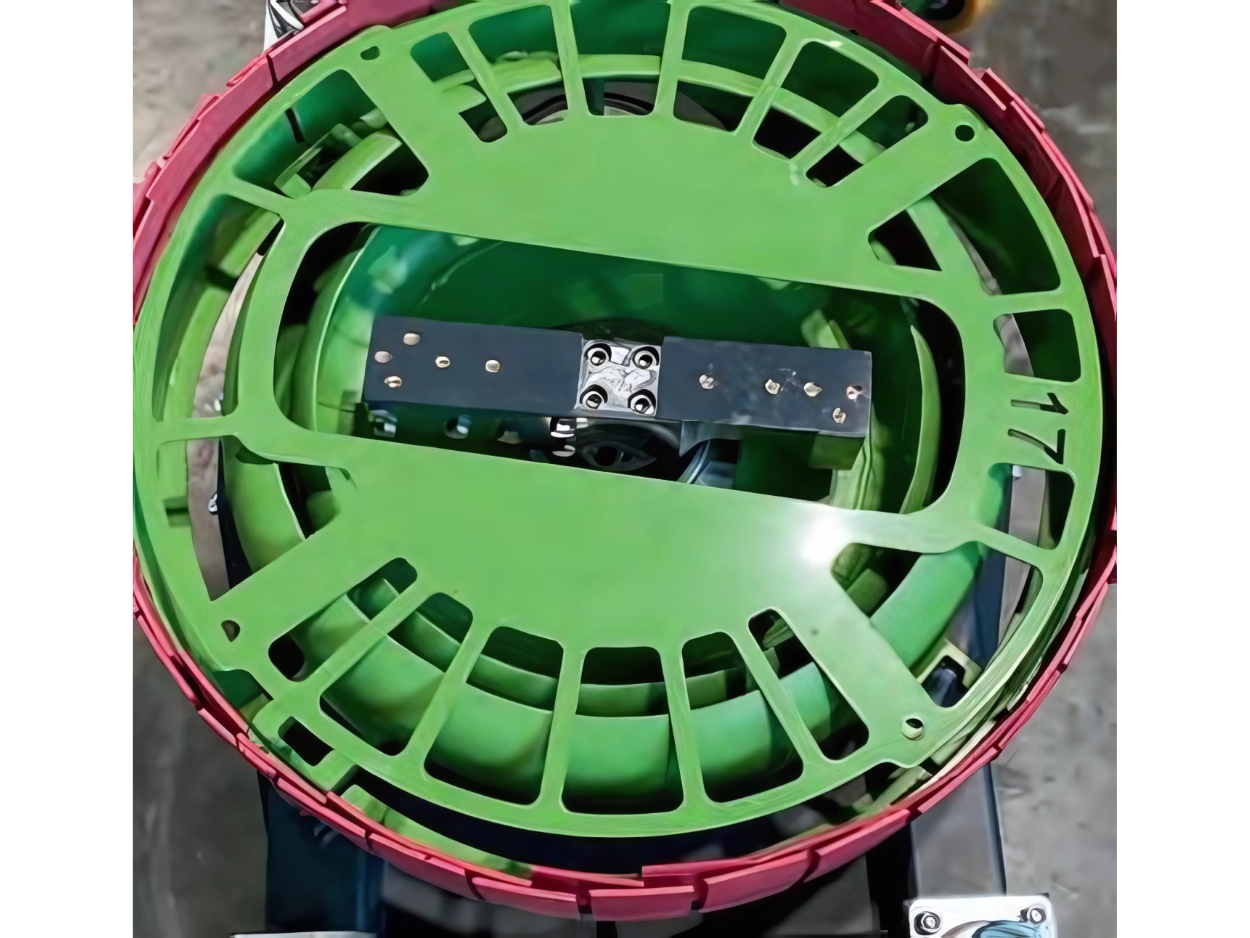

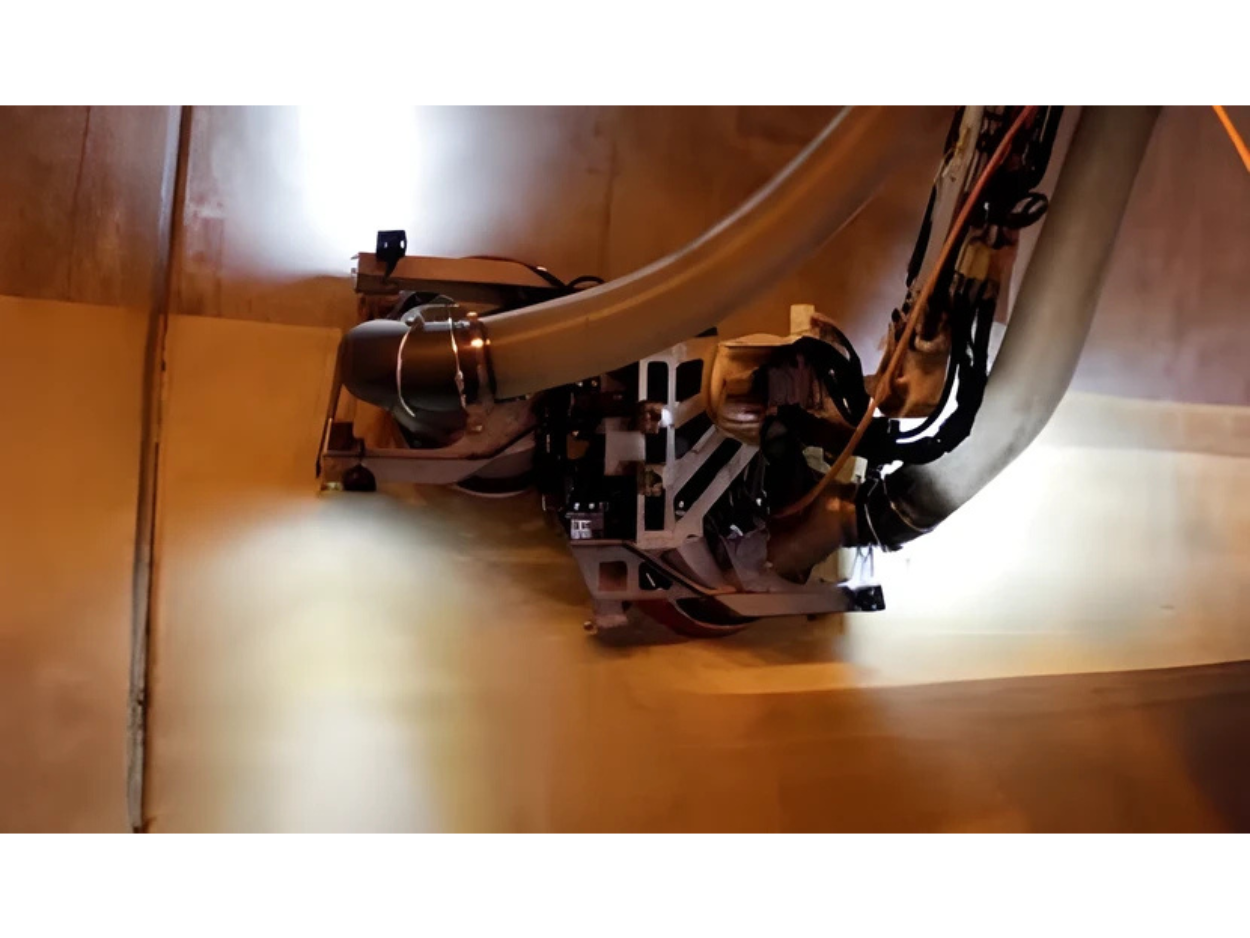

TWISTER TELESCOPE

USED FOR RUBBER REMOVAL

Traffic Lines set standards worldwide with innovative ultra-high-pressure water blasting technologies and intelligent system solutions. In order to provide a better focus on the respective business areas tl traffic-lines GmbH was founded as a sales company of Maschinenbau Cernota GmbH & Co. KG in 2014. Thanks to many years of experience, Maschinenbau Cernota GmbH & Co. KG can respond to a wide variety of needs and special equipment.

USED FOR RUBBER REMOVAL

USED FOR RUBBER REMOVAL

USED FOR RUBBER REMOVAL

USED FOR RUBBER REMOVAL

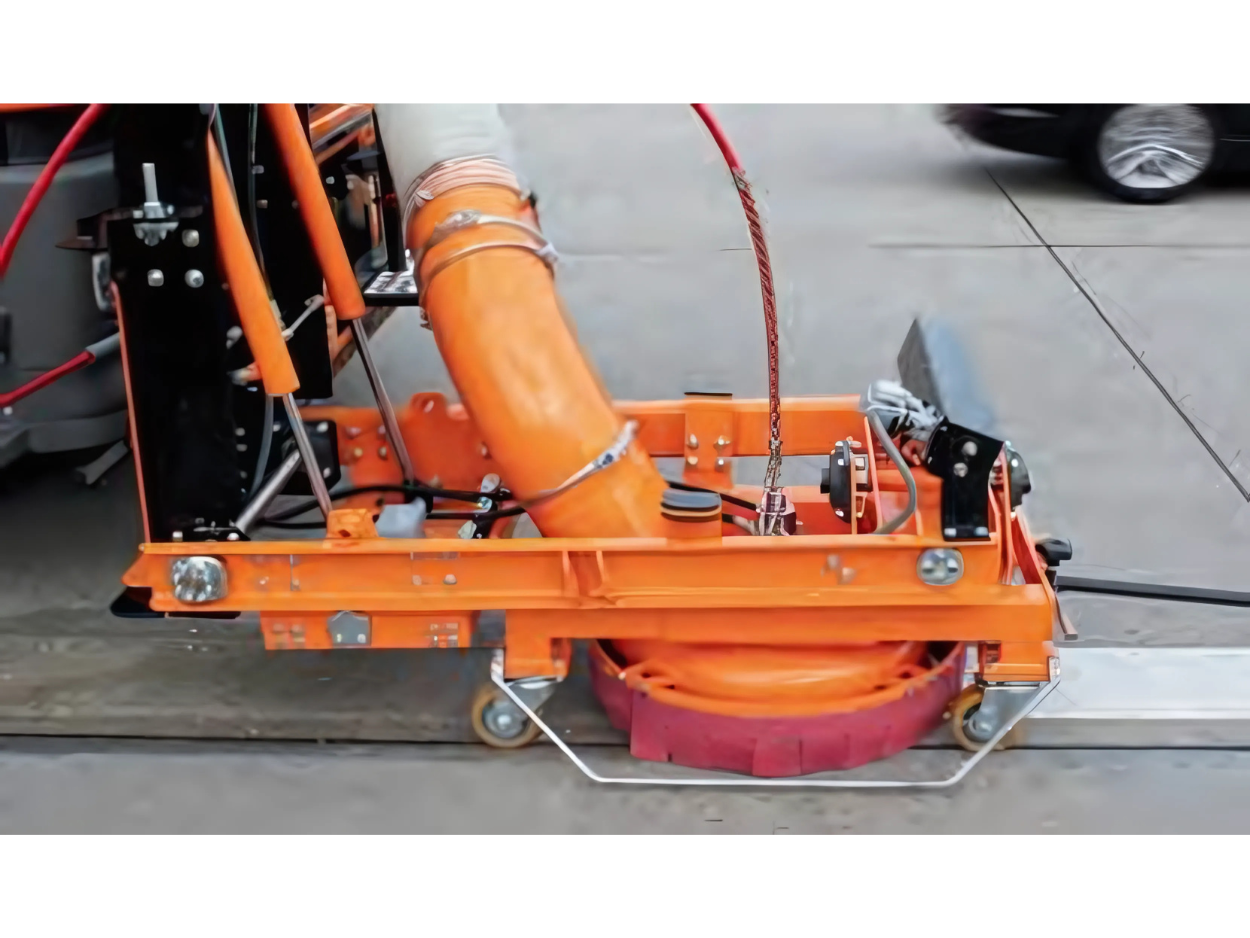

To protect the expansion joints in the asphalt, we have developed a patented joint cover. This can be conveniently lowered by the machine operator from the cab.

The traffic-lines limitation system of water jet pattern ensures that water jets only hit the marking and no adjoining surfaces, thus preventing damages or unwanted surface treatments. The patterns are available in different sizes for perfect fitting to your requirements.

Waste water is treated by an efficient filter and recirculation unit. Filtred water can be used again up to three times for the current cleaning process.

The advantages are obvious:

Environmental protection and resource conservation

Increasing the effective operating time due to reusability of the water

Reducing operating costs

Reduces fresh water consumption

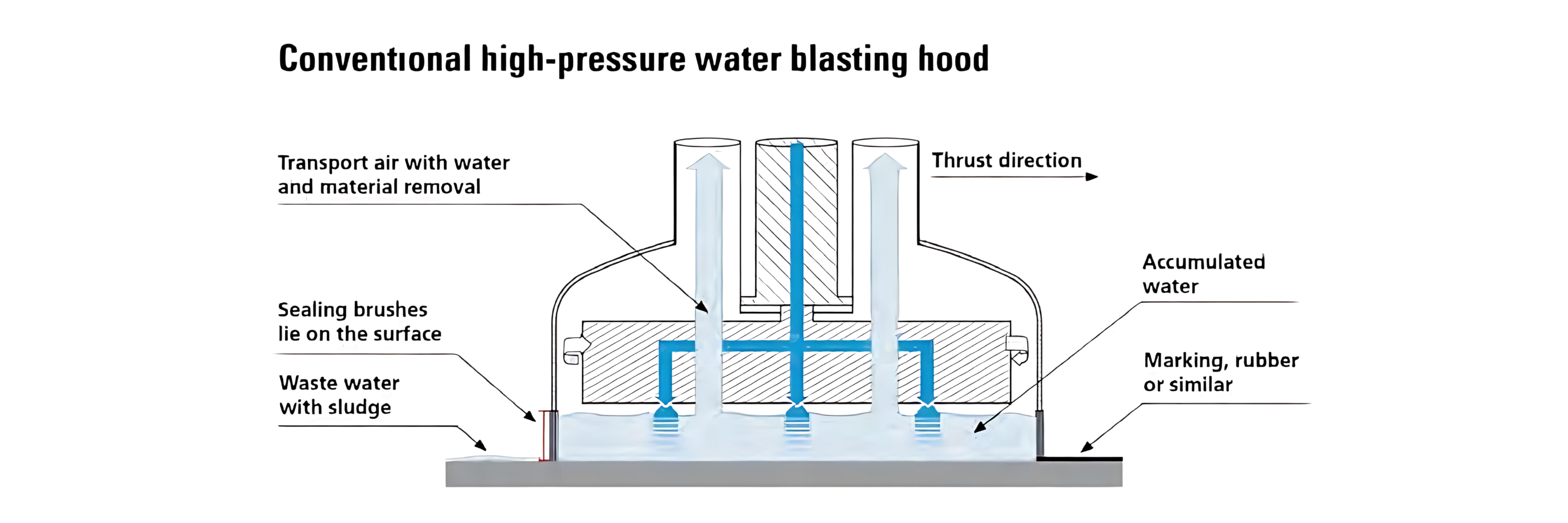

With conventional technology, the milling hood usually lies firmly on the surface to be cleaned with sealing brushes - a closed system is created. During the blasting process, this causes the jet water to accumulate with silt and solids under the hood and the water jet must first penetrate the accumulated water before it hits the surface.

With conventional technology, the milling hood usually lies firmly on the surface to be cleaned with sealing brushes - a closed system is created. During the blasting process, this causes the jet water to accumulate with silt and solids under the hood and the water jet must first penetrate the accumulated water before it hits the surface.

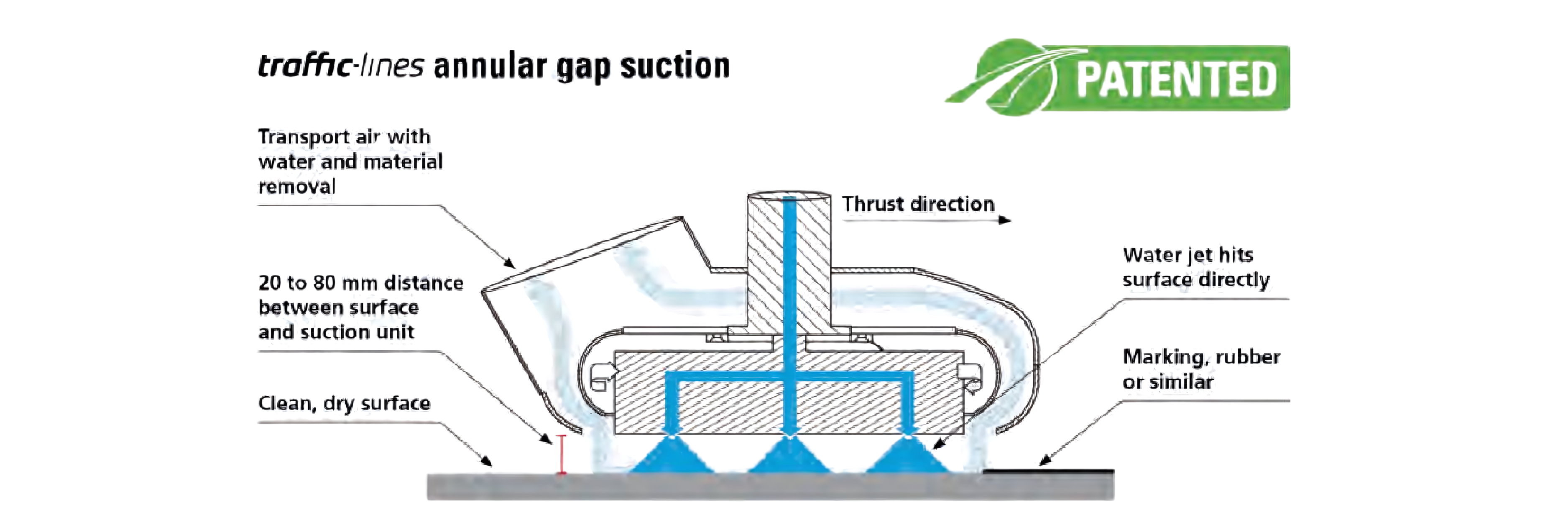

With the patented traffic-lines annular gap suction system, the suction hood does not lie directly on the surface. The resulting air curtain continuously extracts water jets, loosened rubber particles, marking residues and dirt and transports this be the spray bar into the waste water tank.

Loose dirt particles are also already absorbed before the water jet hits. At the same time, the generated air flow volume cools the system during the entire process and absorbs even the smallest liquid particles. The surface is almost dry after cleaning.

The result: No water accumulates in the suction hoods and the water jet generated at ultra-high-pressure hits the surface directly and can develop its optimum cleaning power.

Runways

Aerodrome aprons

Race and test tracks

Road markings and special markings

Markings on airports, race and test tracks, industrial ports

A wide range of surfaces:

- Open porous asphalt,

- Concrete,

- Bituminous pavements,

- Anti-skid pavements,

- Noise-reducing pavements

Aerodrome aprons

Race and test tracks

A wide range of surfaces:

- Open porous asphalt,

- Concrete,

- Bituminous pavements,

- Anti-skid pavements,

- Noise-reducing pavements

Aerodrome aprons

Race and test tracks

Optimising the grip and homogenisation of surfaces